Products

Plate quartz sand production line

Category:

Product

Tel:

E-mail:

Sweep to view

Working video

Introduction

Features:

1. Convenient and quick raw material in-canning.

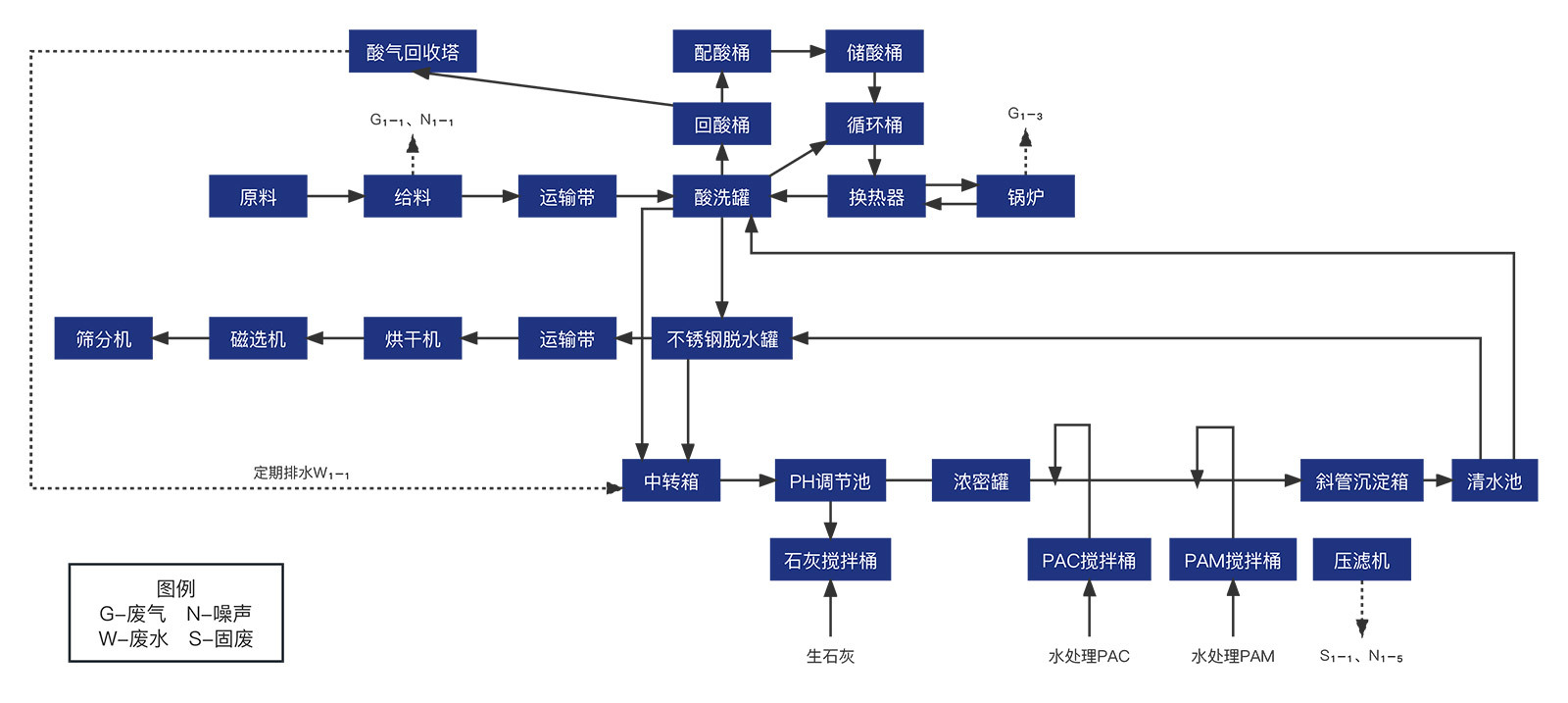

2. Fast heating and sealing reaction speed, good whiteness. The unique acid filtration, acid injection, and cleaning design in the reaction tank achieves more than 90% acid recovery, which can greatly reduce reagent costs and wastewater treatment expenses.

3. Simple cleaning and acid removal, fundamentally removing lighter impurities and fine powder.

4. The dehydration equipment causes no secondary pollution to the sand, with low energy consumption and cost, and high output.

5. Convenient drying operation. The whiteness of the dried sand will not decrease, and no impurities or black spots will be added.

6. Good magnetic selection effect, effectively removing weakly magnetic iron and minerals with color from the sand, reducing the pressure of later color selection.

7. High output of the swing screen screening, good control of particle size and mesh number. This set of equipment has mature technology, and dozens of manufacturers nationwide use the plate quartz sand production line designed and produced by our company.

Principle:

Key words:

Plate quartz sand production line

Previous:

Message

Related Products